Roofcoat FR10

Enquire about this product

Need some advice? Please call us on 01372 743 334

We’re open 9:00am - 5:00pm Mon-Fri

NON-BITUMINOUS ELASTOMERIC ROOFING COMPOUND

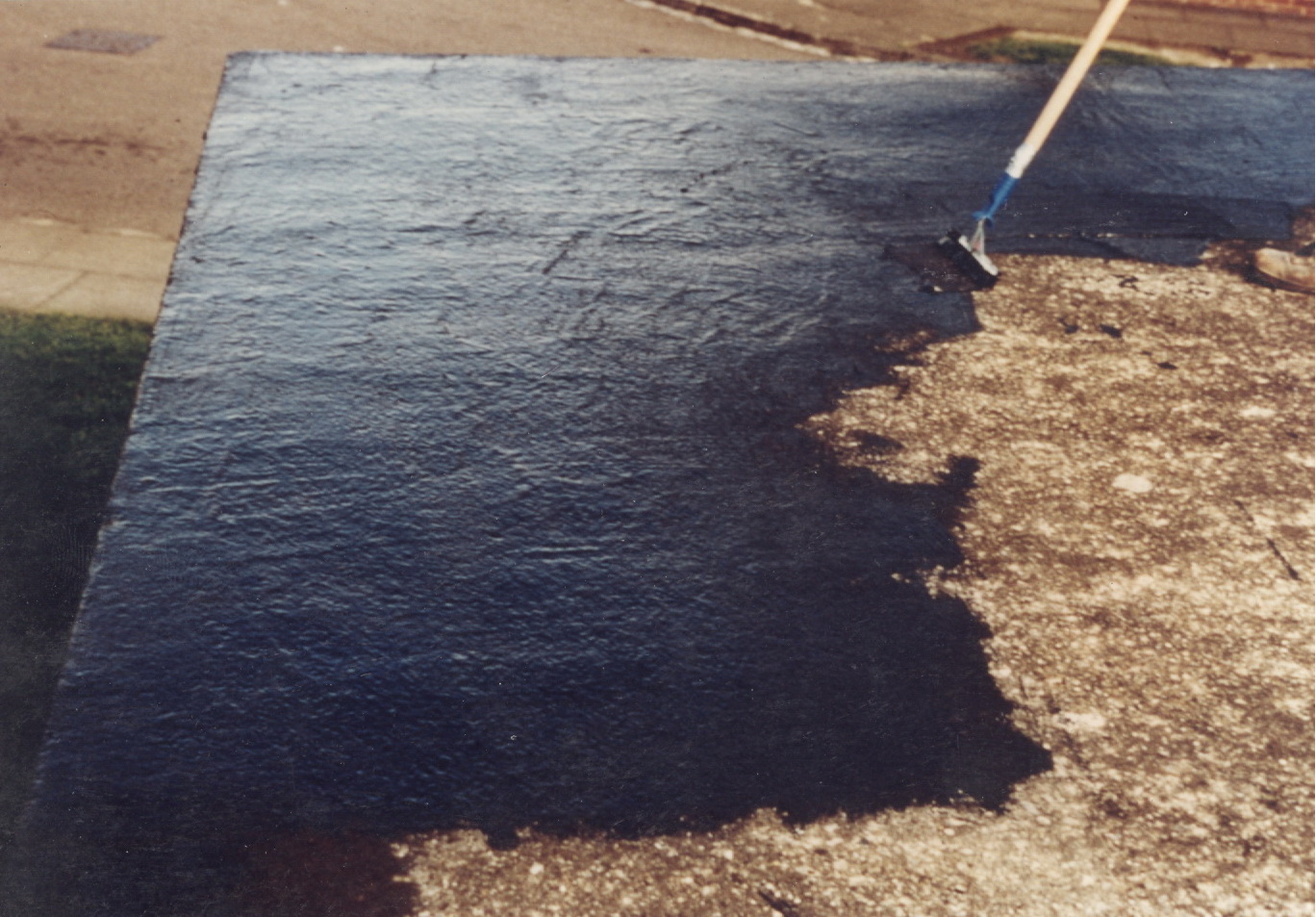

Roofcoat FR10 is a one part moisture curing polymeric waterproofing compound which is elastomeric and has exceptional adhesion to virtually any roofing material. It has been specifically developed to provide instant waterproofing for leaking roofs, is an all-weather product and can be applied even in the wet. ROOFCOAT FR10 can be used to repair specific areas which are leaking or totally waterproof an entire roof. Large cracks, holes, tears, blisters and splits can be easily repaired using ROOFCOAT FR10 SCRIM. The product is multi-purpose and can be utilised on a wide variety of problem areas.

The ROOFCOAT FR10 SYSTEM is easy to use, does not require special primers and gives long term protection of up to 10 years or more.

Benefits

- UP TO 10 YEAR LIFE

- WET WEATHER APPLICATION

- SINGLE COAT WATERPROOFING

- FIBRE REINFORCED COMPOUND

- AVAILABLE IN BLACK, GREY AND WHITE

- ELASTOMERIC WHEN DRY

- OUTSTANDING ADHESION

- CAN BE USED ON A MULTITUDE OF ROOFING SURFACES

- SCRIM FOR REPAIR WORK

- VERY ECONOMICAL

AREAS OF USE

- FLAT ROOFS – can be used as a patch repair or to waterproof the whole roof area. Choice of colour including solar reflective white. Cracks, tears and blisters can be repairs utilising ROOFCOAT FR10 SCRIM.

- ASBESTOS ROOFS – will rejuvenate corrugated sheets, waterproofing and encapsulating the asbestos. In conjunction with ROOFCOAT FR10 SCRIM, ROOFCOAT FR10 can be used to mend split sheets.

- PORCHES – porous leaking areas can be waterproofed easily with one coat of ROOFCOAT FR10

- FINLOCK GUTTERS – cleans out any debris and organic matter. Apply a coat of ROOFCOAT FR10 in a 6” band at the junction of the blocks and embed ROOFCOAT FR10 SCRIM. When dry apply ROOFCOAT FR10 over the full length of gutter.

- VALLEY/CAST IRON GUTTERS – ROOFCOAT FR10 can be used to waterproof gutters and repair leaking joints.

- PLASTIC RAINWATER GOODS – ROOFCOAT FR10 can be used to repair splits, cracks and leaking joints.

- FIBRE CEMENT GUTTERS – use LICHENITE to kill any algae, moss and lichen. Remove all silt, dirt and debris. Apply one coat of ROOFCOAT FR10 to waterproof gutter. Repair joints as (4) above.

- FLASHINGS – leaking defective areas can be repaired with ROOFCOAT FR10.

- BAY WINDOW TOPS – a very common area for leaks, which can be easily and economically rectified with one coat of ROOFCOAT FR10 in desired colour.

- CORRUGATED TIN ROOFS – can be used to repair old and suspect sheets. Spot prime areas of rust with proprietary inhibitor followed by one full coat of ROOFCOAT FR10.

Composition

Non-bituminous, one component polymeric compound with fibres incorporated for strength and special resins giving exceptional adhesion and flexibility.

Appearance

Coloured, viscous compound.

Performance

ROOFCOAT FR10 can be used to repair leaking roofs. It will adhere to all conventional roofing materials and surfaces including felt, asphalt, bitumen, concrete, asbestos, corrugated tin and lead. ROOFCOAT FR10 is not affected by UV or IR rays. It is elastomeric and will cater for seasonal movement.

Coverage

ROOFCOAT FR10 should be applied at a rate of not less than 1kg per square metre for flat surfaces. Allow for additional ROOFCOAT FR10 on corrugated or aggregated surfaces.

Availability

Supplied in 5kg tins and 20kg drums.

Colours

Black, Grey and White.

Applications & Storage

ROOFCOAT FR10 can be applied by brush, soft broom, trowel or the specially designed ROOFCOAT FR10 SPREADERS. It should not be applied in conditions where the ambient temperature if 5°C and dropping. Protect from frost and store in a dry location out of direct sunlight. Shelf life 6-9 months in unopened containers.

Support Products

ROOFCOAT FR10 SPREADERS - 12.5cm (5”)

ROOFCOAT FR10 SCRIM - 10m x 12.5cm (5”)

Health & Safety

Flammable. Flash point 42°C. Do not breathe vapour. Avoid contact with skin. In the event of eye contact or ingestion seek medical advice.

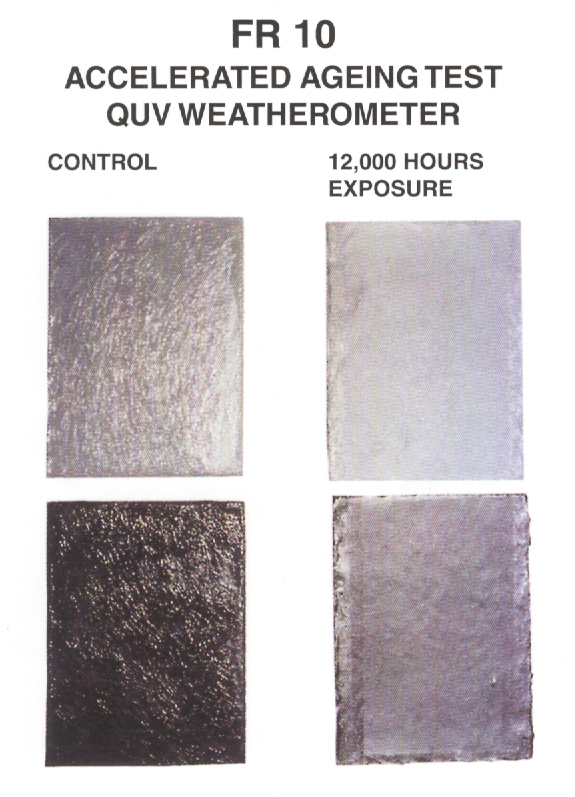

INDEPENDENT WEATHEROMETER TEST - Laboratory Report

MATERIAL: Roofcoat FR10

PROPERTY: Ageing and Heat Resistance

TEST METHOD: QUV Weatherometer

TEST SPECIMEN: One coat brush applied to mineral board, dried at room temperature.

TEST PROGRAMME: Exposure cycles, 4 hours UVB @ 65°C, 4 hours condensation @ 50°C

RESULTS:

3,000 hours = surface is matt due to chalking which cleans off to leave a good sheen. Coating is integral and providing the substrate with protection against moisture penetration.

12,000 hours = without failure.

Colour good, surface dull due to chalking. Signs of erosion of binder and fibres exposed. Coating still integral and intact with substrate protected against ingress of moisture.

COMMENTS: This is an accelerated ageing test which combines many factors, such as effect of heat, ultra-violet light and moisture in continuous cycles. Because specific conditions of ageing can vary greatly, this test cannot be quantitative. ROOFCOAT FR10 was tested in comparison with a competitor’s product which claimed to have a 10 year natural ageing span. Under our test conditions it crazed and cracked within the first 3,000 hours of test. NB. 1,000 hours is equivalent to 3 years natural weathering.

FIRE RESISTANCE

ROOFCOAT FR10 has been tested for fire resistance and conforms to DIN4102 Part 7.

SPECIFICATION

- Remove all organic matter, loose and peeling coatings and roof aggregates (chippings etc). Drains and gutters should be protected against blockage.

- Clean the surface of any remaining dirt and debris, preferably by suitable high pressure water jetting or stiff bristle bass brush.

- Surfaces previously contaminated with moss, lichen and algae growth must be treated with LICHENITE. Apply one coat by brush or spray at a coverage not exceeding 10 square metres per litre. Allow 24 hours before proceeding.

- Splits, cracks and blisters should be repaired with ROOFCOAT FR10 SCRIM. Apply one coat of ROOFCOAT FR10 to the area to be repaired, cut scrim to the desired length, embed in the wet ROOFCOAT FR10 and apply a second coat. Blisters in felt should be star cut, ROOFCOAT FR10 applied under the flaps and the flaps rebedded. Strengthen the repair with ROOFCOAT FR10 SCRIM and apply a further coat of ROOFCOAT FR10 over the repair.

- ROOFCOAT FR10 and ROOFCOAT FR10 SCRIM should be used to bridge and fill large gaps and cracks. Silicone substrates should not be treated with ROOFCOAT FR10.

- To the prepared surface apply a generous coat of ROOFCOAT FR10 in selected colour by ROOFCOAT FR10 SPREADER, brush, soft broom or trowel. DO NOT THIN. Work away from area immediately being treated and towards a suitable escape exit. Do not walk on the newly coated surface whilst application is in progress or until the coating has cured and dried. Curing time 2-3 days.

- CLEANING: Brushes, trowels and spreaders should be cleaned immediately after use in white spirit.